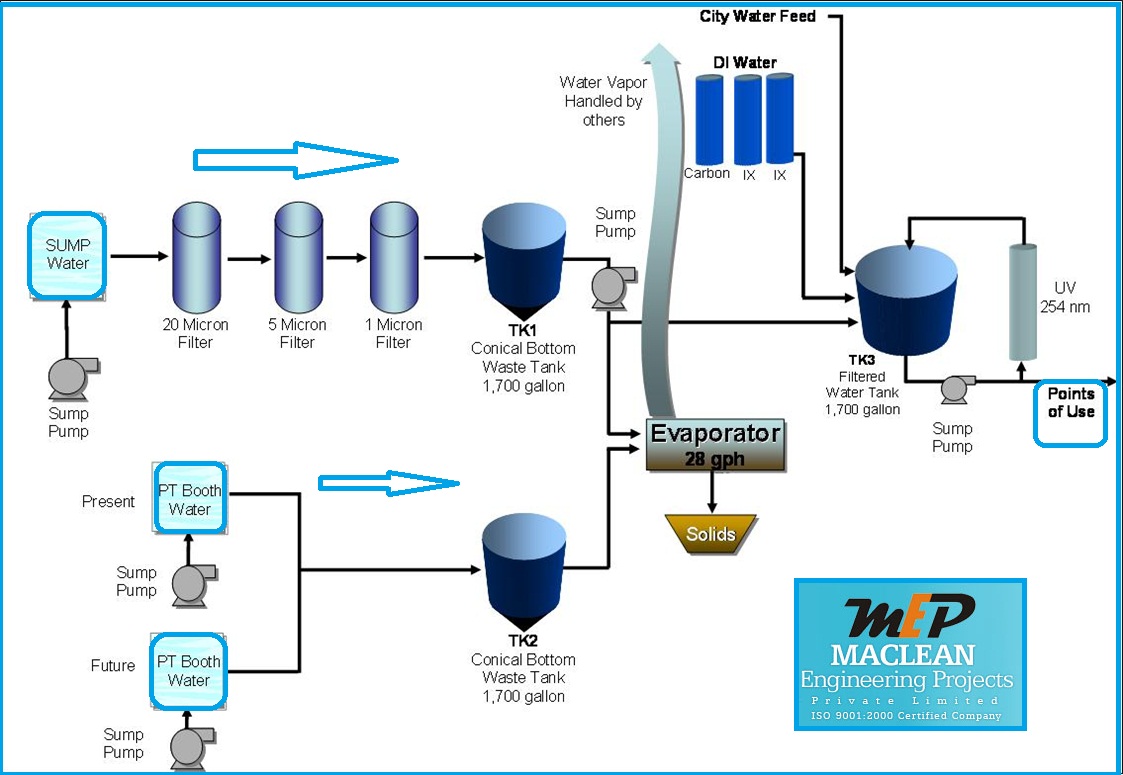

Zero Liquid Discharge System - ZLD

Zero Liquid Discharge process is the most advanced waste water treatment technology

that recycle and purify the produced waste water. This process is highly advantageous

for different industries and municipal corporations for effectively reusing their

waste water and effluent to achieve zero liquid discharge. The process is cost effective,

environment friendly and no effluent or discharge is left.

This process of waste water treatment provides various environmental and economic

advantages to the plants. All the water is used and recycled and no effluent is

discharged from the plant. This technology is highly appropriate in the areas where

water there is shortage of water.

The Zero Liquid Discharge process helps in the reduction of carbon footprint and

the recovery of highly pure water for reuse. The technology also get rid of liquid

waste by converting it into disposable dry solids. The ZLD process is based on thermal

processes and membrane process or the combination of the two processes that is called

hybrid process.

The process of Zero Liquid Discharge System is used in following industries:

- Power Generation

- Oil & Gas

- Hydrocarbon Processing

- Chemical Processing

- Metals & Mining

- Food & Pharmaceutical

UF Membrane Filtration System

Specifications for UF Module::

| MODULE | DFM-0407 | DFM-0830 | DFM-0852 |

| Effective Surface Area | 7 sq mt | 30 sq mt | 52 sq mt |

| Designed Flux | 0.21 to 0.84m3/h | 0.9 to 3.6 m3/h | 1.5 to 6.0 m3/h |

| Dimensions | 90*1, 140 mm200*1, 475 mm | 200*2, 155 mm | |

| Housing Material | UPVC | ||

| Potting Material | Polyurethane | ||

| Gasket Material | NBR | ||

| Filtration Metod | Dead-end or Cross Flow | ||

| Weight(Wet) | 15 kg | 50 kg | 80 kg |

| Weight(Dry) | 8 kg | 25 kg | 45 kg |

| OPERATING CONDITIONS | |||

| Max. Intel Pressure | 300 kpa | ||

| Max. Operating TMP | 200 kPa | ||

| Max. Temperature | 10-55 deg celsius | ||

| Flow Direction | Outside to Inside | ||

| Filtrate Turbidity | 0.1 NTU | ||

| Filtrate SDI | 2.0 | ||

| pH Range | 1-12 | ||

Advantage of UF Module:

- Large-scale module with high permeability

- Large-scale module with high permeability enables high flux with compact installation space

- External Pressure and Dead-end or Crossf tow Filtration Method

- An external pressure type filtration is efficient to filter the raw water of high turbidity

- Both dead-end filtration or cross-flow filtration method can be chosen, as per the water quality change of raw water. High Safeness

- The module is made of safe elements that can be used for drinking water procuction. As nominal NWCO 150,0a, it is suitable for removing Colon Bacillus and Pathogenetic Nlicrozon, such as Cryptosporidium

- Small footprint and high recovery rate

- The module structure that achieve high installation density realize small footprint. The unique backwash method ensures high recovery rates of 95%, or more

- Long Life span and chemical resistancy

- Hollow fiber membranes manufactured with PVDF proprietary technology provide superb mechanical strength and chemical resistance